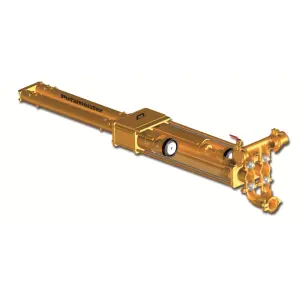

Part of the KOV series which is characterized by its straightforward design and high reliability; the suction and delivery cylinders of this piston pump are connected by indirectly operating balls. Omission of actively driven elements results in a good value pump with the maximum availability. Pasty materials such as mortar or Bentonite, even with a content of foreign substances up to 1” (20 mm) in size can be conveyed without any difficulty with a pumping pressure up to 1305 psi (90 bar) and an output of up to 78.5 yd³/hr (60m³/hr).

Depending on specific individual demand, the balls and valve seats can be supplied in different materials and coatings and a maintenance aperture permits easy and rapid replacement of the valve balls.

Key Features

- Base frame with oil pan and bulkhead panel for hydraulic connections

- Delivery cylinder which is multi layer chrome-plated 250 µm

- Piston material and seals in Perbunan

- Waterbox for lubrication, cooling and optimum accessibility of the delivery piston

- Pressure relief valve in the pump head

- Suction ball / pressure ball made of steel (depending on medium gummium sheathing)

- Safety devices according to European Machinery Directive 2006/42 / EC

- Electrically controlled back-pumping

- Mechanical flow adjustment

- All sensors are wired to one centralized terminal box

- Central terminal box for all electrical connections on the operating side of the pump

- Hydraulic control system VHS-EHS according to pump size